Scientists uncover molecular marvel behind spider silk's super powers

- 08 February, 2026

- 13:23

Scientists have identified the molecular interactions that give spider silk its exceptional strength and flexibility, opening the door to new bio-inspired materials for aircraft, protective clothing and medical applications, and even advancing our understanding of neurological conditions such as Alzheimer's disease, Report informs referring to the King's College London website.

The findings, published in the journal Proceedings of the National Academy of Sciences by researchers at King's College London and San Diego State University (SDSU), establish general design principles that could guide the development of a new class of high-performance, sustainable fibres.

The joint research is the first to show how the amino acids that make up spider silk proteins interact to behave like molecular "stickers."

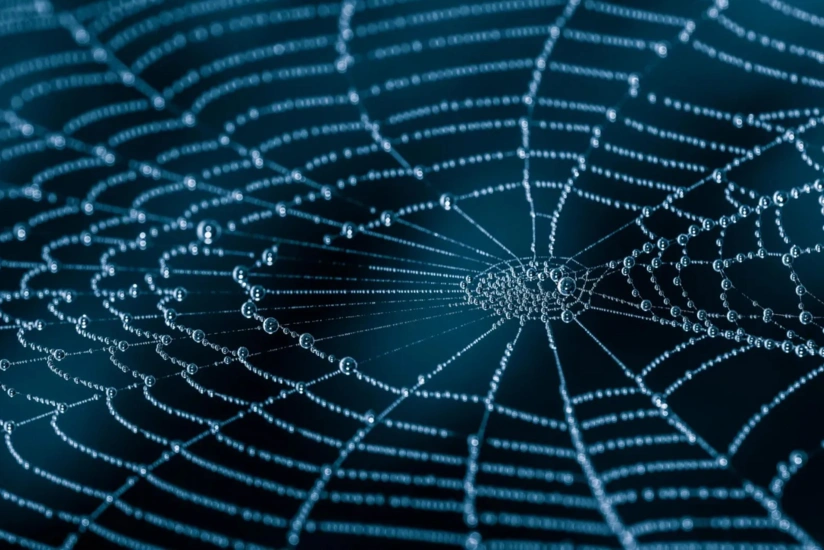

Spider dragline silk is stronger than steel by weight and tougher than Kevlar - the material used to fabricate bullet-proof vests. The exceptional natural material forms the framework of a spider's web and is also used for suspension, and researchers have long sought to understand how to recreate its unique properties.

Dragline silk is produced in a spider's silk gland, where proteins are stored as a concentrated liquid known as "silk dope" before being spun into solid fibres.

While it has been known that these proteins first condense into liquid-like droplets before being extruded into fibres, the molecular mechanism linking this process to the silk's final structure has remained unclear.

The interdisciplinary team of chemists, biophysicists and engineers used a combination of advanced computational and experimental tools - including molecular dynamics simulations, AlphaFold3 structural modelling and nuclear magnetic resonance spectroscopy - to demonstrate that the amino acids arginine and tyrosine interact to trigger the initial clustering of the proteins.

Crucially, these same interactions persist as the silk fibre forms, helping to create the complex nanostructure responsible for its exceptional mechanical performance.

Gregory Holland, SDSU professor of physical and analytical chemistry, who led the US side of the research, said one of the most surprising outcomes was how chemically sophisticated the process turned out to be.

He suggested the findings could therefore extend into human health research.